Last week, the Swiss stock exchanges experienced their worst fall since the financial crisis of 2008 (Keystone / Arne Dedert)

The coronavirus has laid bare the fragilities and complex dependencies generated by globalisation. American-Swiss professor Suzanne de Treville, a specialist in helping firms relocate their industrial activities to the west, hopes that this crisis will trigger some major soul-searching.

Covid-19 is on the verge of bringing the world economy to its knees. From Asia to Europe and the United States, the new coronavirus that sprung from China has had a crippling effect on the economy, causing stock markets around the world to nosedive and dealing a severe blow to global growth.

But this crisis has also revealed the risks and dependencies of long production lines and supply chains. Using tools derived from quantitative finance, Suzanne de Treville, professor of operations management at the University of Lausanne, has set out to prove that it is more advantageous to produce locally than abroad, even for expensive Switzerland.

swissinfo.chexternal link: In just a few weeks, the coronavirus has managed to wipe out the entire global economy. Have our leaders underestimated the fragility of globalisation and the systemic risks it entails?

Suzanne de Treville: Most managers are not able to integrate shocks like the coronavirus into their decision-making models. They assume that everything will always go well, whereas we know that this is not the reality. One out of 100 or 500 major problems will occur. The risks associated with lengthening the production chain are considerable and very often ignored. Therefore it is essential to train future managers in logical and systemic thinking. Together with my assistant Jordi Weiss, we have developed software and simulation models that make it possible to calculate the real costs of outsourcing.

+ Here is an open access version of the simulatorexternal link

swissinfo.ch: Could the coronavirus crisis serve as a wake-up call?

S. d.T.: One can only hope so. The consequences of the covid-19 epidemic on people’s lives and the economy are serious enough to trigger conversations that were unthinkable just a few weeks ago. From the mid-1990s, we started relocating everything to China and developing countries, without really thinking about the risks and dependencies that this would entail. Today, the awakening is brutal, with many business leaders questioning how such stupid decisions could have been taken at the time.

swissinfo.chexternal link: Yet the world today is more interdependent. China accounts for nearly one-fifth of the world’s production and is an integral part of global supply chains. Chinese tourists spend more than $260 billion a year. Is it truly possible to turn back the clock?

Over the past 20 years, we assigned innovation to rich countries and production to “low-cost” economies. However, innovation cannot be completely decoupled from industrial activities. Industrial activities also provide many jobs. For every industrial job, you create between five and ten jobs in the supply chain or in the services sectors. That’s a lot. Likewise, it is no longer possible today to keep production and service operations separate, as had been the case up to now. The two must now be closely linked.

swissinfo.chexternal link: What do you mean?

S. d.T.: Let’s take the example of the textile industry. The fast-fashion giants are currently flooding their shelves with cheap clothes produced under poor working conditions in China and Bangladesh. Often, however, only 10-20% of this merchandise is sold and the rest is destroyed to make way for new collections. This is totally absurd, economically, socially and ecologically. The textile industry is the second most polluting industry in the world.

In the US, the department of commerce is using a tool developed by my laboratory over the last six years to repatriate this industry to the US. This would create jobs there and put an end to this absurd waste.

swissinfo.ch: How will they tackle this?

S. d.T.: In future, when you want to buy a shirt, you will have the opportunity to go to a personal advisor who will scan your body to design a tailormade garment for you. The order will then be placed with a small production facility located nearby or in an area of the US that needs these jobs. After 40 or 50 uses, your shirt will be returned to the shop where the fibre will be recycled and reused.

This service will be offered at a differentiated rate depending on whether you need your shirt for a wedding the following week or only three months from now. It’s a bit like air travel: people travelling in first or business class pay a larger share of the flight price relative to people travelling in economy. Compared with what the major fashion retailers offer today, this circular economic model is very flexible and adapts much better to the customer’s needs.

swissinfo.ch: By working with the Trump administration, aren’t you facilitating a protectionist economic policy that threatens the global balance?

S. d.T.: The use of our tool began under the Obama administration. In fact, the person in charge of this issue at the US Department of Commerce has been in office for 34 years and has therefore worked under both Republican and Democratic presidencies. Creating jobs and developing industrial activity is certainly the least politicised issue in the US. There is unanimous agreement on the need to curb the deindustrialisation and impoverishment that is hitting many parts of the country.

swissinfo.ch: What you say may be music to the ears of American and European politicians but might be less appealing to leaders of developing nations that owe their leap forward to industrialisation in recent decades.

S. d.T.: You are mistaken. When I was a professor at the Massachusetts Institute of Technology (MIT) in 2014, there were a lot of Chinese students attending my classes. They were convinced that the way I saw things represented the hope of China. Today, Chinese factories are a living hell for workers. Over-industrialisation is also causing terrible damage to people’s health and to the environment. China’s leaders have already realised that they can no longer continue along this path. Instead of flooding the world with cheap products, they are concentrating more on value-added products and the internal market. In agriculture, interesting circular economy models are also being developed. Change is underway.

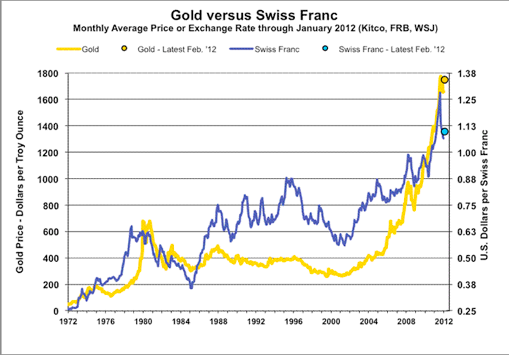

swissinfo.ch: And how about Switzerland? Can it really afford to maintain a competitive industry despite high production costs and a strong national currency?

S. d.T.: It’s clear that despite the strong franc, the Swiss economy is doing well. For many companies, this is a detail that is very easy to offset. Switzerland has a well-trained and motivated workforce because young people can work in modern, dynamic and attractive factories. Proximity to some of the world’s best universities and research centres is also an important advantage. In my research, for example, I have calculated that Switzerland’s flexibility offers technology companies an added value of 15 to 100%. And that’s without factoring its top-notch infrastructure, whether in the area of transport or public administration. We have in our hands all the advantages needed to develop a strong and competitive industry in Switzerland.

The real cost of relocation

Suzanne de Treville has developed the Cost Differential Frontier Calculator (CDF) – a tool proving that offshoring is much more expensive than business leaders realized until now.

This calculator provides an estimate of full-lead-time demand volatility assuming that the forecast-evolution process is smooth.

The Cost-Differential Frontier uses quantitative finance techniques to calculate the mismatch cost arising from long lead times, answering the question “How much cheaper does a long-lead-time supplier have to be to compensate for the increase in demand-volatility exposure?”.

This videoexternal link further elaborates the basic concepts underlying the tool. The CDF was developed by Professors Suzanne de Treville and Norman Schürhoff of OpLab at the University of Lausanne’s Faculty of Business and Economics (HEC). The underlying theory is developed in an article published in the Journal of Operations Management that is available through the US Department of Commerce AceTool websiteexternal link.

This version of the CDF calculator assumes that the demand forecast evolves with a constant instantaneous volatility.

Translated from French by Dominique Soguel

Full story here Are you the author? Previous post See more for Next postTags: Business,newsletter